Adapted to your needs

The AWA team is there to adapt to your particular situation.

Because every project is unique, the AWA outdoor mobile station is available with a multitude of different options and configurations in order to suit your specific needs.

SHOWCASING TAILORED SOLUTIONS

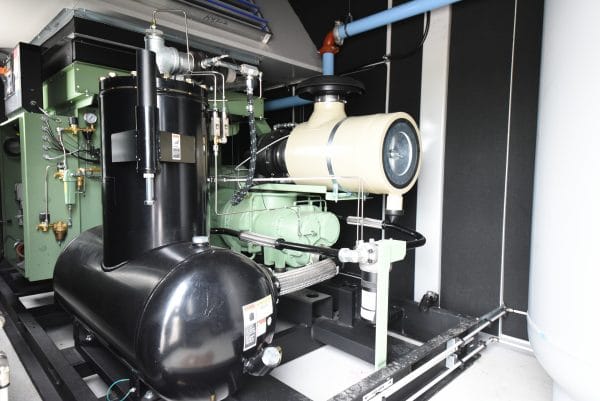

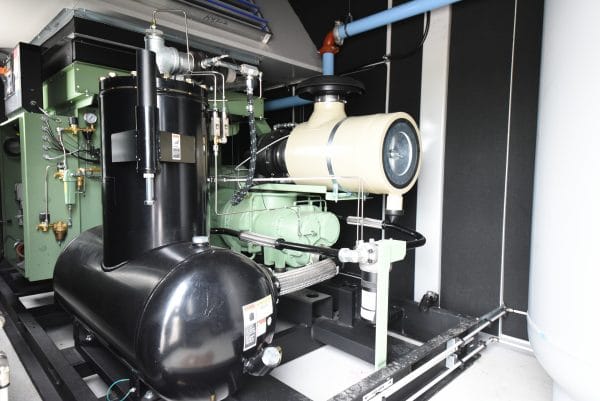

All makes and models of compressors can be installed in our AWA including Class 0 Oil-Free Models ISO 8573-1.

Heat recovery for external use.

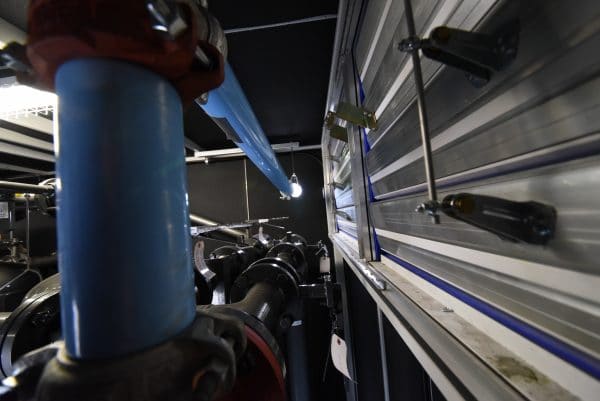

Stainless steel ventilation louvers.

Structural modification for lifting by crane.

Remote control and monitoring CCRM.

Custom paint jobs according to your specifications.

Multi-voltage electrical panels.

Sound or visual alarm equipment.

Non-standard widths.

Putting Their Trust in Our Expertise

Special Custom Made Projects

Reclaim the space for production

The AWA compressor was installed at a state-of-the-art manufacturing facility dedicated to producing high-quality solid surface countertops for the home builders and remodeling industry. Compressed air plays a crucial role in various aspects of the countertop production process, offering a range of benefits and efficiencies.

In the plant, compressed air is utilized for a variety of tasks. One essential application is powering pneumatic tools and equipment used in the fabrication of countertops. From cutting and shaping the solid surface material to polishing and finishing the surfaces, compressed air-driven tools ensure precise and efficient operations, contributing to the overall quality of the countertops.

Compressed air is also employed in the operation of automated machinery and systems within the plant. This includes pneumatic actuators and cylinders that facilitate the movement and positioning of components during the manufacturing process. The reliable and consistent power provided by the compressor located into the AWA ensures smooth and accurate operations, resulting in consistent and high-performing countertops.

By installing the compressor into an AWA and moving it outdoors, the plant not only optimized its compressed air supply but also freed up valuable indoor space for other production activities. This strategic decision enhanced productivity and efficiency within the facility, enabling a streamlined countertop manufacturing process.

With the operation of two powerful 50 HP compressors, the facility ensures an ample and reliable supply of compressed air to meet the demanding needs of countertop production, ensuring consistent quality and exceptional craftsmanship.

Mass-produced units with electrical particularities

The following project is an example that proves our ability to produce multiple identical units simultaneously.

The following project exemplifies our capability to produce multiple identical units simultaneously, showcasing our expertise and efficiency.

In accordance with the customer’s specifications, we successfully manufactured 36 identical units for this project.

These units held a special requirement: the ability to operate on two different electrical frequencies, ensuring functionality in both Europe and North America. Our dedicated engineering team meticulously designed the electric models to meet the required standards set by the client.

Additionally, this project presented a challenge due to the assembly’s operation in a desert climate. While AWAs are typically designed to operate in temperatures up to 104°F, we implemented modifications to the ventilation system specifically for this project, enabling the assembly to be rated for temperatures up to 131°F. The entire AWA assembly, including the compressor and electrical panel, has been meticulously certified to operate flawlessly even under these high-temperature conditions.

If you have specific electrical and climatic requirements for your project, rest assured that the AWA team is fully equipped to assist you in designing the customized solution you need.

Welcome to the world of explosion proof!

This client had specific equipment operation requirements that demanded explosion-proof capabilities, presenting a significant challenge for our AWA company.

Machines operating under such stringent requirements must have all their electrical components rated as explosion-proof.

An “explosion-proof” environment refers to an area where the presence of flammable gases, vapors, or combustible dusts creates a potentially hazardous situation. In these environments, any electrical equipment used must be designed and constructed to prevent the ignition of such hazardous substances. Explosion-proof enclosures and components are specially engineered to contain any sparks, arcs, or heat generated within them, thereby reducing the risk of an explosion.

With this in mind, our engineering team embarked on designing a mobile air compressor unit tailored to meet the client’s unique needs.

Every single electrical component underwent meticulous evaluation and was modified to achieve Explosion Proof certification. Finally, we delivered a 40′ long cabinet to the client, fully certified as Explosion Proof.

If your equipment operates in environments that require certifications, such as Explosion Proof, rest assured that we have an AWA enclosure designed for you!

A large project

When a prominent steel company sought to upgrade their compressed air system, they opted for the installation of 3 x Sullair TS 32-450 compressors and 3 x 2500 CFM desiccant dryers. One of the primary motivations behind this decision was to reduce energy consumption by leveraging Sullair’s variable displacement spiral valve technology. This innovative technology enabled the steel company to precisely match air supply to demand, resulting in reduced energy costs during periods of low air demand.

The customer faced challenges due to the presence of cold, damp, and dusty areas where the units would be situated. AWA enclosures proved to be the ideal solution. By housing the units within AWA enclosures, we were able to maintain the internal temperature at a consistent 70°F, ensuring optimal performance while safeguarding the investment from dust and debris commonly found in the mill environment.

Additionally, considering the long piping distance from the All-Weather Air units to the plant, we made the decision to install a flow controller. This measure ensured a steady supply of air pressure to the plant, eliminating fluctuations and maintaining consistent and reliable air pressure levels.

Through the integration of Sullair technology, AWA enclosures, and the implementation of a flow controller, we successfully provided the steel company with an upgraded compressed air system that not only optimized energy consumption but also protected the equipment and ensured a stable air supply for their operations.

Lack of space on site?

Lack of space on site? We offer a high-rise solution!

This project located in Alberta is composed of 2 custom designed AWAs. One contains a 200HP compressor and the other a 300HP compressor TDF.

The client was running out of space on site, no space was available inside their facilities, and nothing possible outside. Normally the AWAs contain the air tanks, but in this case, given the size of the required air tanks, it was impossible to place them inside the AWAs.

The engineering team came up with a custom-designed solution to maximize the space: place the air tanks above the AWA. A suitable solution was put in place which included a structure hidden in the AWA capable of supporting the impressive tanks in a completely safe way. The biggest tank is 6000 gallons!

The AWA team is here to offer creative solutions for the lack of space!

A mountain project without a floor!

A ski center wanted a new compressed air system dedicated to the production of its artificial snow. He therefore opted for a non-lubricated screw compressor.

Our AWAs provide floors that can support the significant weight of centrifugal compressors and sustain their vibrations. We have the expertise to offer an AWA floor that is equivalent to the manufacturer’s requirements.

The installation of this project had to be done according to the manufacturer’s requirements of being installed on a solid base. After consulting with the customer, we opted for installing the compressor directly onto the cement foundation with the AWA portable cabinet placed around it. This option of custom air compressor cover, offered certain advantages: Cost of installation of the compressor was reduced as well as reducing manufacturing time of the AWA cabinet. This AWA is installed near the top of the mountain, near the ski slope.

AWAs have no throughput or HP limits. We can easily accommodate equipment such as electric screw compressors, lubricated or not, as well as centrifugal machines.

The AWAs can be installed on concrete slabs, as in this case, or the equipment can be fixed to the floor of the AWA.

When the compressor manufacturer requires the installation of concrete foundations, we also have the solution.

We are able to offer you the necessary enclosure!

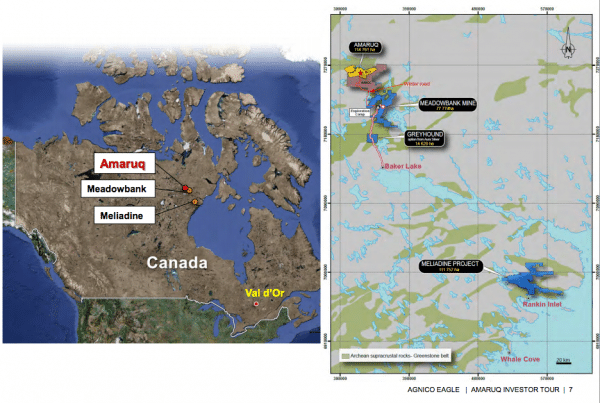

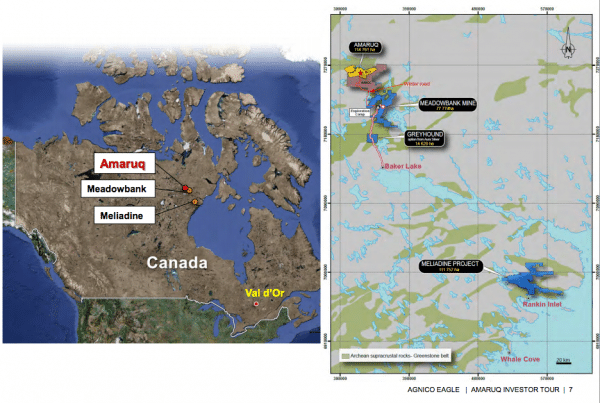

An expedition to the far north!

Transporting AWAs over Long Distances: Meeting Special Packaging Requirements for Extreme Conditions

The AWA underwent a complete redesign to be able to operate in this exceptionally cold environment. To meet the customer’s requirements of operating in temperatures as low as -50°F, the AWA received double insulation. In addition to the regular insulation, a layer of urethane was added to the AWA. This enhancement enabled the AWA to function in the extreme conditions found in the low Arctic region of Canada.

The site is extremely remote and accessible only by boat. To ensure transportation, the AWA was packed in a vacuum bag and placed in a wooden crate. The AWA traveled from the Port of Quebec to northern Hudson Bay. This packaging protected the AWA from the highly corrosive sea air.

Today, the AWA excels in an open-pit gold mine within a polar environment, where operating machinery faces the harshest of challenges. From sub-zero temperatures and freezing winds to rugged terrain and demanding workloads, the AWA’s robust design and advanced insulation ensure reliable performance in the most extreme mining conditions.

Keywords: expedition to the Far North, AWA, cold environment, double insulation, urethane, low Arctic region of Canada, remote site, transportation, vacuum bag packaging, wooden crate, Hudson Bay, open-pit gold mine, polar environment, extreme mining conditions.